Clamps & Vises

Hold work still while you cut, drill, glue, or shape. Bar clamps reach across wide panels. Vises grip pieces solid to the bench. Spring clamps grab quick when you need a third hand.

Clamps & Vises

Hold work where you need it. Each clamp and vise grips solid so you can focus on the cut.

Quick Bar T-Track Clamp

One-handed operation. Squeeze to close, release to lock. T-track head fits bench dog holes and jigs.

Shop Now

2″ Plastic Spring Clamp

Quick grip for light work. Spring-loaded jaws grab and release fast. Won’t mar wood surfaces.

Shop Now

Straight Line Toggle Clamp

Mounts to jigs and fixtures. Locks down work with lever action. Repeatable pressure for production work.

Shop Now

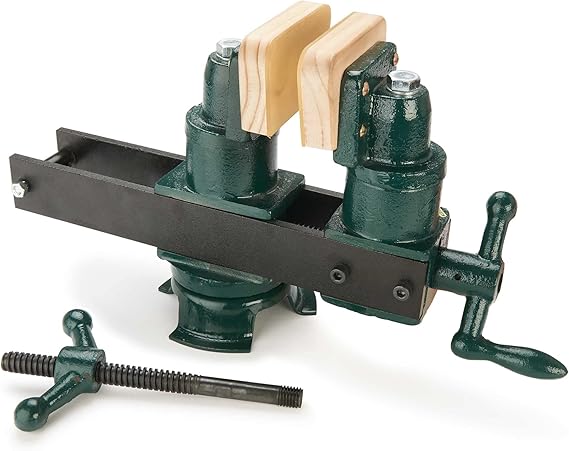

Patternmaker’s Carving Vise

Tilts and rotates to any angle. Holds carved work solid while you shape. Ball joint locks tight.

Shop Now

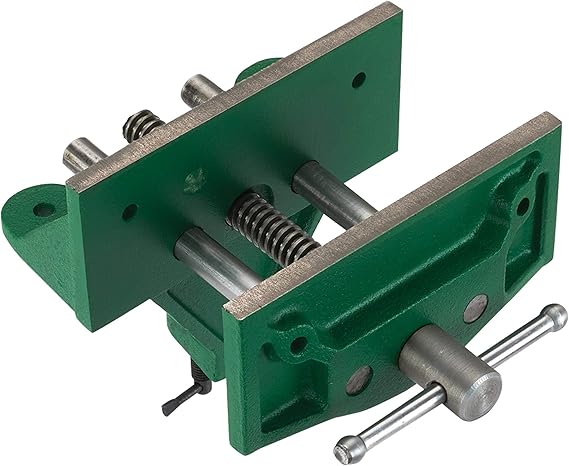

6″ Woodworking Vise

Mounts under bench front. Quick-release lever opens jaws fast. Dog holes in both jaws for panel work.

Shop Now

Universal Vise

Holds round, square, or odd-shaped work. Pipe jaws and flat jaws included. Swivels to any angle.

Shop NowAbout Clamps & Vises

Hold work still while your hands stay free to cut, drill, or shape. Clamps grab pieces together. Vises lock work to the bench. Both keep things from moving when they shouldn’t.

What Clamps Do

Clamps press glue joints tight until they dry. They hold boards steady for cutting or drilling. Bar clamps reach across panels. Spring clamps grab quick for small work. C-clamps squeeze thick stock. The right clamp depends on what you’re holding.

What Vises Do

Vises bolt to your bench and hold work solid. Woodworking vises grip boards for planing or sawing. Carving vises tilt and rotate so you can reach all sides. Universal vises hold round or odd-shaped pieces. They free both hands for the tool.

How Much Pressure

Glue joints need even pressure across the whole surface. Clamping for cutting or drilling needs enough grip to stop movement but not so much it crushes the wood. Vises should hold firm without marking soft woods.

Which Ones to Get

Start with four bar clamps for glue-ups. Add a few spring clamps for quick holds. A bench vise covers most holding needs at the workbench. Buy more clamps as projects demand them – you can never have too many.

Who Needs These

Glue panels, clamp joints, and hold assemblies square while fasteners set

Hold boards for cutting, drilling holes straight, and keeping work from slipping

Any Shop

Every woodworker needs something to hold work. Clamps and vises solve that problem

Common Questions

Everything you need to know about clamps and vises before you buy.

Clamps are portable tools you can move around and adjust to different sizes. They’re perfect for holding pieces together during gluing, assembly, or when you need temporary holding power.

Vises are permanently or semi-permanently attached to your workbench. They provide extremely high clamping pressure and are ideal for tasks like sawing, drilling, planing, and carving where you need both hands free to work.

Start with bar clamps in a couple of different lengths. They’re the most versatile and handle the majority of woodworking tasks – from gluing boards together to assembling furniture.

Add a few spring clamps next for quick, light-duty work. They’re inexpensive and surprisingly useful for holding pieces while glue dries or for temporary positioning.

You can never have too many. A realistic starter set includes four to six bar clamps in various lengths, half a dozen spring clamps, and a couple of C-clamps.

As you build larger projects, you’ll find yourself needing more. Many woodworkers accumulate dozens over time. Buy quality clamps as you need them rather than cheap ones that fail when you need them most.

They can leave marks or dents if you’re not careful. The metal jaws concentrate a lot of pressure on a small area.

Always use scrap wood blocks between the clamp jaws and your workpiece. This spreads the pressure and protects your wood. Some clamps come with padded or plastic jaw covers, but a piece of scrap works just as well.

For general woodworking, look for a vise with jaws between 7 and 10 inches wide. This handles most projects without being overly large or expensive.

The jaw opening matters too – get at least 5 to 8 inches of opening capacity. Smaller vises work for detail work and repairs, while larger ones are needed for heavy-duty projects.

Woodworking vises have wider, smoother jaws that won’t damage wood. They’re designed to distribute pressure evenly across delicate surfaces.

Metalworking vises have serrated jaws that grip hard materials but will mar wood surfaces. If you only work with wood, get a proper woodworking vise. For mixed work, consider both or add wooden jaw covers to a metal vise.

Keep the threads and sliding parts clean. Wipe off sawdust and glue drips after each use. A light coat of paste wax or machine oil on metal surfaces prevents rust.

Store clamps in a dry place, off the ground. Hang them on wall racks if possible. Check screws and handles periodically for tightness. Well-maintained clamps will last decades.

Yes, and many woodworkers do this regularly. Clamp one jaw of a handscrew or bar clamp to your workbench edge, and the other jaw becomes a makeshift vise.

This works well for light tasks and saves money when you’re starting out. However, a proper vise gives you more stability and frees up your clamps for other work.