Turning Tools

Steel that shapes spinning wood. Gouges hollow bowls, skews smooth cylinders, parting tools cut clean. Tools built to ride the rest and cut what the lathe brings around.

Turning Tools

Tools that cut spinning wood. Each one handles its own part of the work.

5-Piece Mini Turning Tool Set

Small tools for small work. Pens, bottle stoppers, small bowls. Five common shapes in sizes that fit tight spaces.

Shop Now

3-Piece Pen Turning Set

Three tools for pen turning. Roughing gouge, skew, and parting tool. Covers the basic cuts from blank to finish.

Shop Now

1/8″ Diamond Parting Tool

Thin blade cuts narrow grooves and parts off finished pieces. Diamond shape gives clearance without binding.

Shop Now

Carbide Replaceable Turning Tool

Carbide cutter stays sharp longer than steel. Rotate or replace the tip when it dulls. No grinding needed.

Shop Now

Turning Tool Storage Rack

Holds tools within reach of the lathe. Keeps edges protected and tools organized. Mounts to wall or bench.

Shop Now

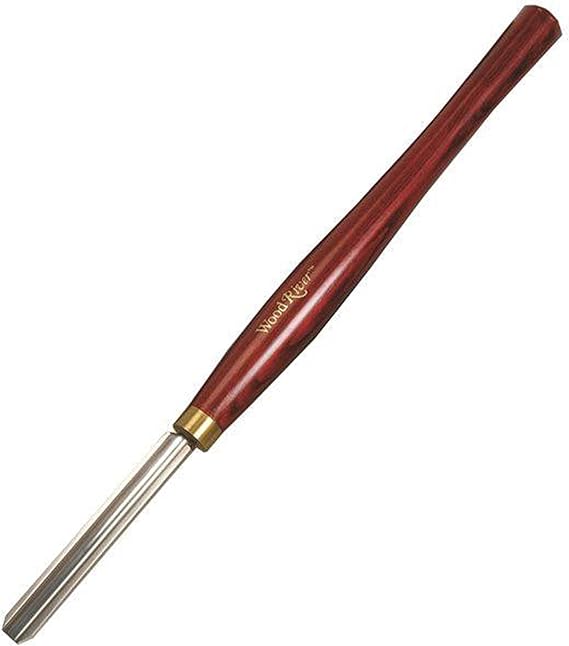

3/4″ Roughing Gouge

Rounds square stock into cylinders. Heavy cuts that remove waste fast. The first tool you reach for on spindle work.

Shop NowAbout Turning Tools

Steel that rides the tool rest and cuts wood as it spins. Hold the tool steady, move it into the cut, and the lathe does the rest.

What Turning Tools Do

Gouges hollow bowls and round spindles. Skews smooth cylinders and cut details. Parting tools cut grooves and separate finished pieces. Each tool rides the rest and cuts where you point it.

Different Types

Roughing gouges take square stock to round. Bowl gouges hollow and shape. Spindle gouges work beads and coves. Skews cut shoulders and smooth surfaces. Parting tools separate work from waste.

How to Use Them

Rest the tool on the rest, bevel to the wood. Move the handle to control the cut. Let the spinning wood do the cutting – push too hard and the tool grabs. Sharp edges and light pressure give clean cuts.

Keeping Them Sharp

Grind the bevel on a wheel when the edge rounds over. Touch up between grinds with a slip stone. Sharp tools cut with less effort and leave smoother surfaces than dull ones.

Who Uses These Tools

Hollow vessels, shape curves, and finish surfaces on bowls and platters

Turn small parts with control, cut details, and part off finished pieces

Furniture Makers

Round legs, turn spindles, and shape any round parts furniture needs

Common Questions

What you need to know about turning tools before you buy.

Spindle gouges have a shallow flute and work best on wood spinning between centers – table legs, tool handles, pens. They cut beads, coves, and details.

Bowl gouges have a deeper flute and heavier build. They handle the forces of hollowing bowls and turning end grain. Use the right gouge for the job.

Start with three tools: a roughing gouge to round stock, a spindle gouge for shaping, and a parting tool to cut grooves and part off work.

Add a skew for smoothing and a bowl gouge if you want to turn bowls. Build your set as you learn what you need.

WoodRiver turning tools come with a factory grind. Most will cut wood out of the box, but you’ll get better results after grinding them to your preferred bevel angle.

Every turner grinds their tools differently. Take time to learn proper grinding angles for each tool type.

HSS (high-speed steel) tools need grinding to sharpen. They offer more control and leave cleaner cuts once you learn to use them.

Carbide tools have replaceable tips that you rotate or swap when dull. No grinding needed, but less control and they can leave rougher surfaces on some cuts.

Depends on the wood and how much you’re turning. Softwoods might let you turn for an hour. Hard or abrasive woods dull tools faster.

When the tool stops cutting cleanly or you need more pressure, stop and sharpen. A sharp tool makes turning easier and safer.

No. Roughing gouges are only for spindle work between centers. Using them on bowls or face work can break the tool and cause injury.

Bowl gouges are built stronger to handle the forces of turning end grain and hollowing. Always use the right tool for the job.

Yes, if you’re using HSS tools. Turning dulls edges fast, and stones won’t keep up. A bench grinder with a jig lets you sharpen in seconds.

Carbide tools don’t need grinding – just rotate or replace the cutter tips. But most turners eventually learn HSS for better results.